2025-09-05 パシフィック・ノースウェスト国立研究所(PNNL)

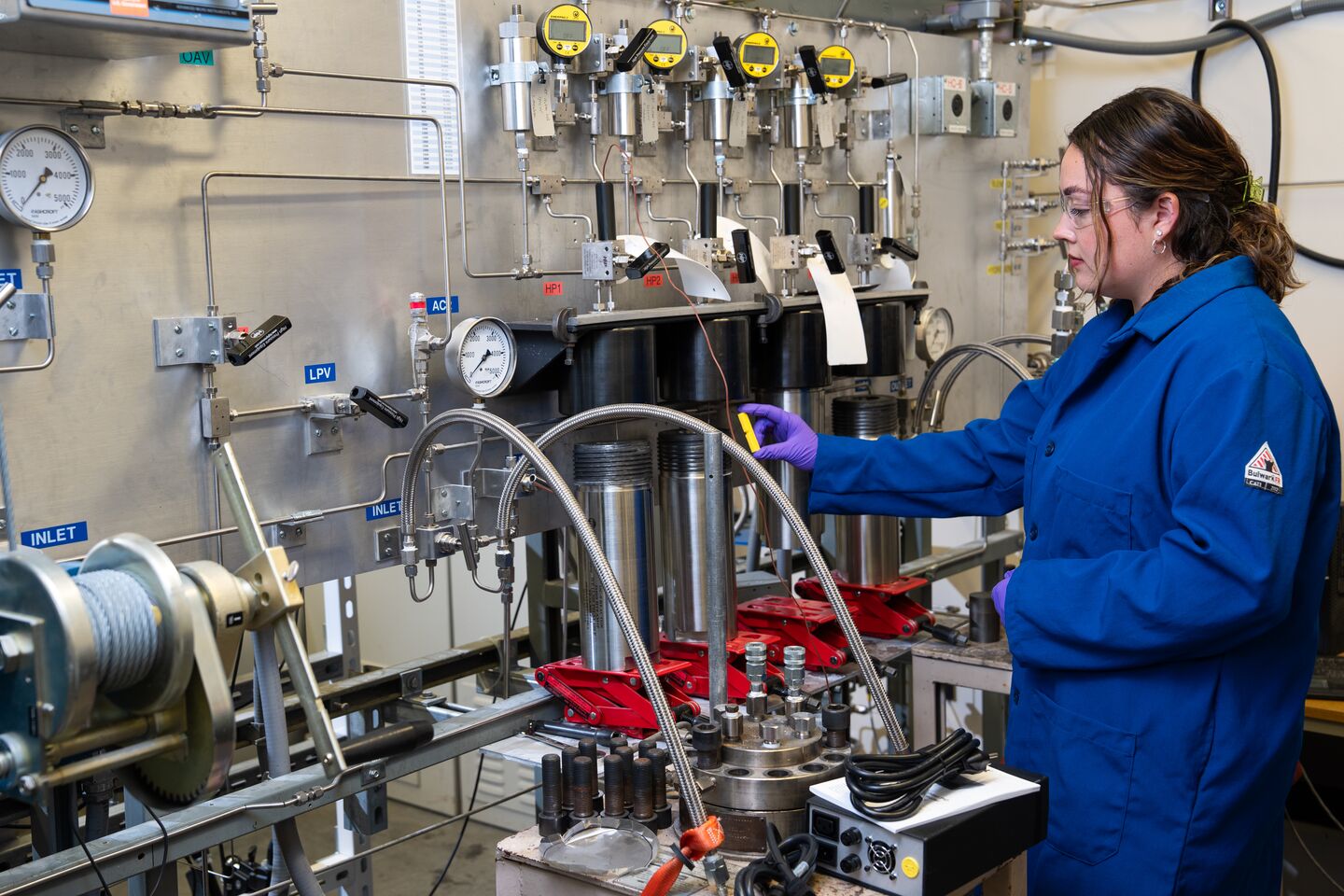

Pacific Northwest National Laboratory is equipped with advanced capabilities for testing materials’ compatibility with hydrogen fuel, like the hydrogen pressure vessel pictured here. (Photo by Andrea Starr | Pacific Northwest National Laboratory)

<関連情報>

- https://www.pnnl.gov/publications/have-us-natural-gas-pipelines-forged-path-future-hydrogen

- https://asmedigitalcollection.asme.org/PVP/proceedings-abstract/PVP2024/88506/V004T06A018/1209585

水素ガス環境下におけるポリマーパイプライン材料の形態変化に関する原位置・非原位置研究 In-Situ and Ex-Situ Studies on the Morphology Changes of Polymer Pipeline Materials for Use in Hydrogen Gas Environments

Kevin Simmons,Seunghyun Ko,Wenbin Kuang,Yao Qiao,Yongsoon Shin,Kee Sung Han,Nalini Menon

Pressure Vessels and Piping Conference Published:November 14, 2024

DOI:https://doi.org/10.1115/PVP2024-123520

Abstract

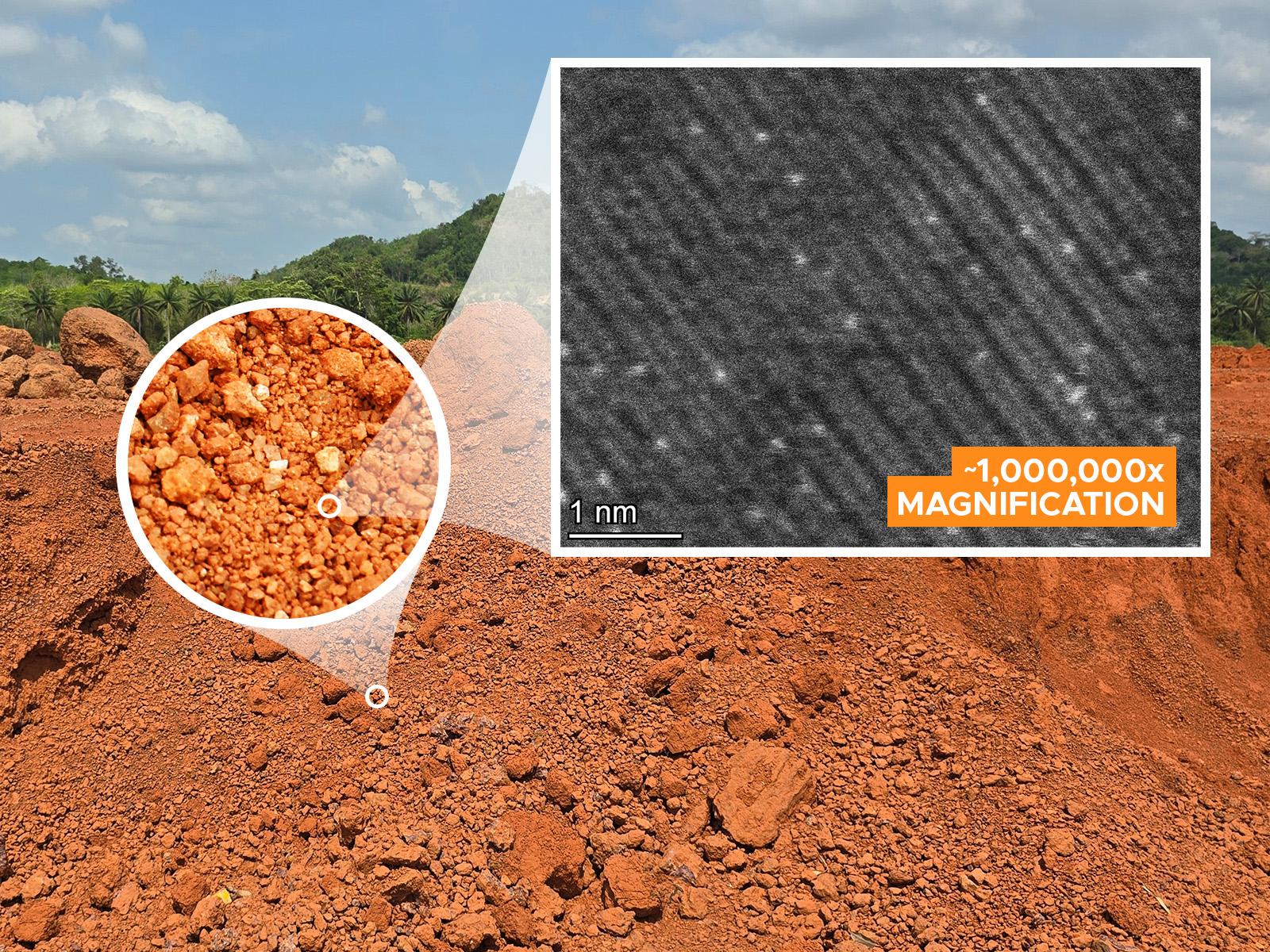

The US natural gas infrastructure is a national asset that could be used to deliver hydrogen and hydrogen blends of natural gas as a pathway to reduce carbon emissions. The distribution system comprises nearly 50% plastic pipe composed of medium- and high-density polyethylene materials (MDPE and HDPE). While these materials perform adequately for natural gas, research on their hydrogen compatibility is essential to understand if any immediMDPEate and long-term risks are associated with hydrogen addition. The Blended Gas CRADA, a HyBlend project, has established a comprehensive test method for evaluating MDPE and HDPE of various plastic resin compositions of pipeline material in pure hydrogen and 20% hydrogen/80% methane blends. Both in-situ and ex-situ measurements were performed to capture hydrogen-induced changes in the polyethylene material’s crystalline, amorphous, and interphase regions.

We investigated MDPE and HDPE pipeline materials made from different polymer resin systems to evaluate the effects of hydrogen gas. The materials were characterized by their density, diffusion coefficient, free volume ratio, and degree of crystallinity. Various advanced characterization methods, including in-situ high-pressure NMR, ex-situ XRD, ex-situ DSC, and ex-situ TDA, were used to analyze the effects of changes in crystalline, amorphous, and interphase regions due to gas exposure. Time-dependent post-decompression quasi-static tensile tests were conducted to explore the effects of gas exposure time on the mechanical behavior of the pipe materials.

This work will highlight the time sensitivities during and after gas exposure. The correlation between gas-induced polyethylene morphology changes and the associated material performance will be addressed for the intended applications. These studies will show that polyethylene resin composition and material exposure are important factors when considering whether hydrogen gas affects pipeline materials positively or negatively.